TGSK epicyclic gears with their high grade of reliability and vibration performance are made for applications, demanding high speeds without vibration issues and toothing wear.

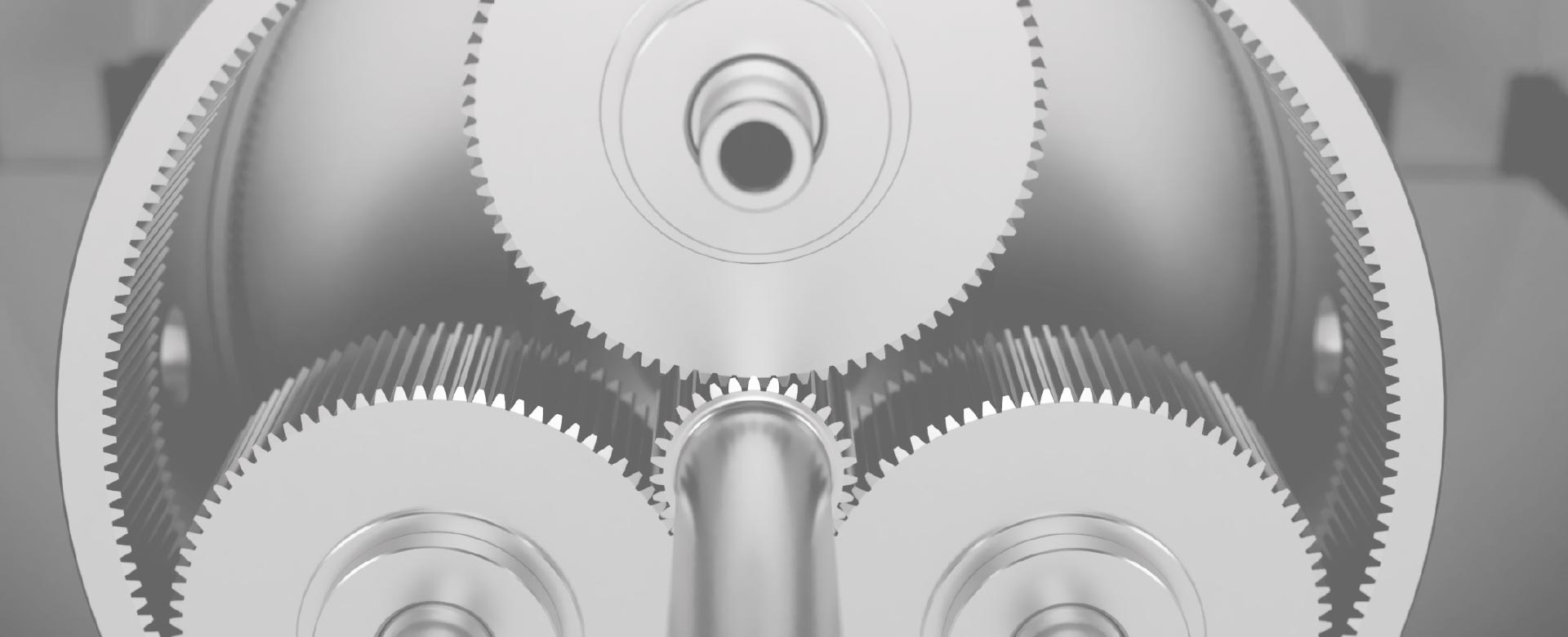

For increased requirements towards running, vibration and noise performance we use double helical gear design. Where multiple teeth in mesh at a time guarantee increased performance.

Power generation: Generators driven by gas, steam, water or expansion turbines for power generation

Oil & gas: Energy recovery using expansion turbines

(Petro-)Chemical: Compressors and pumps driven by electric motors

Test stands: For compressor / turbine or motor development, balancing machines, aerospace applications

| Power | up to 20 MW |

| Spees | up to 45.000 rpm |

| Efficiency | up to 99,3 % |

| Ratio | up to i = 12 (one state design) |

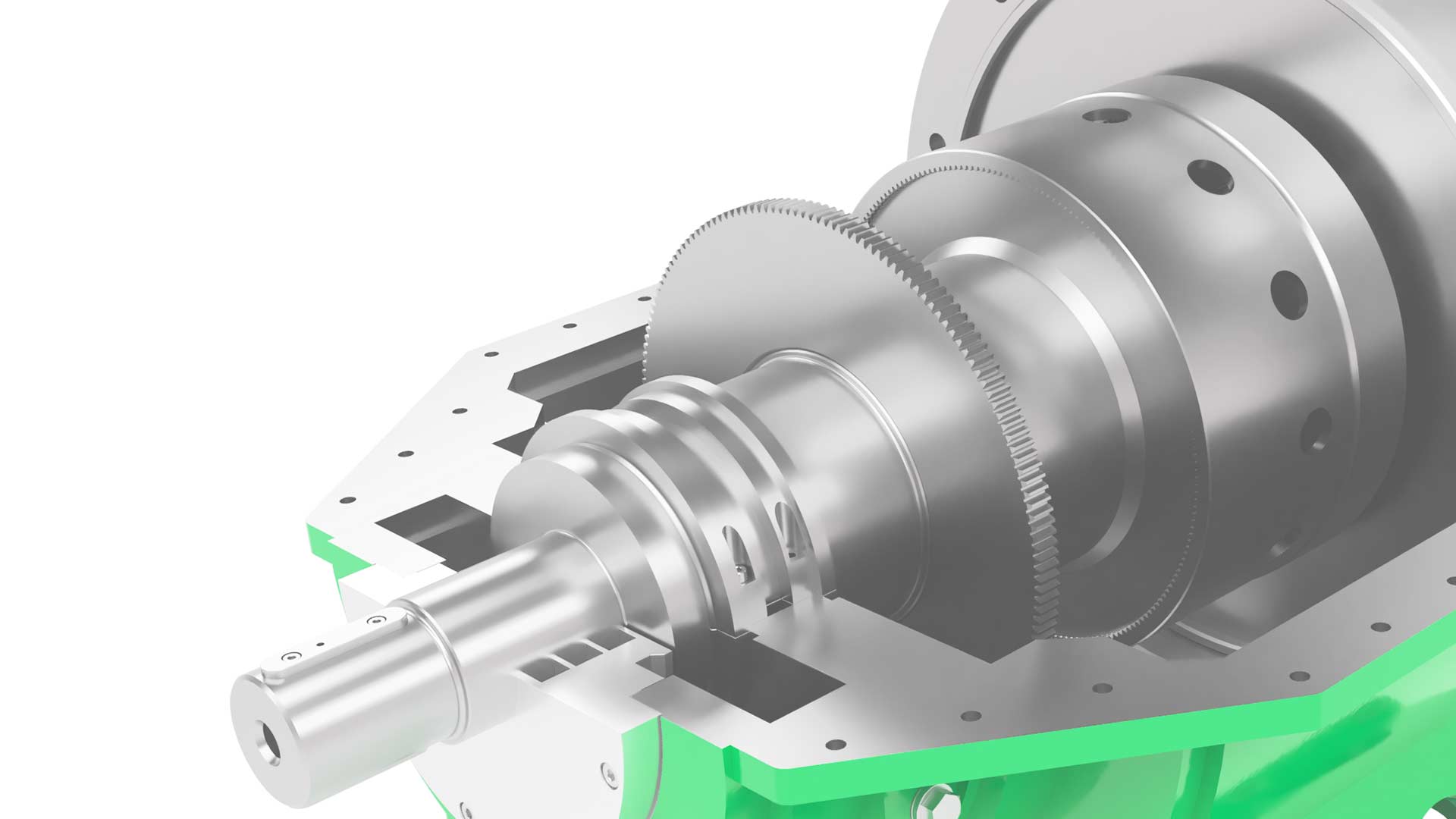

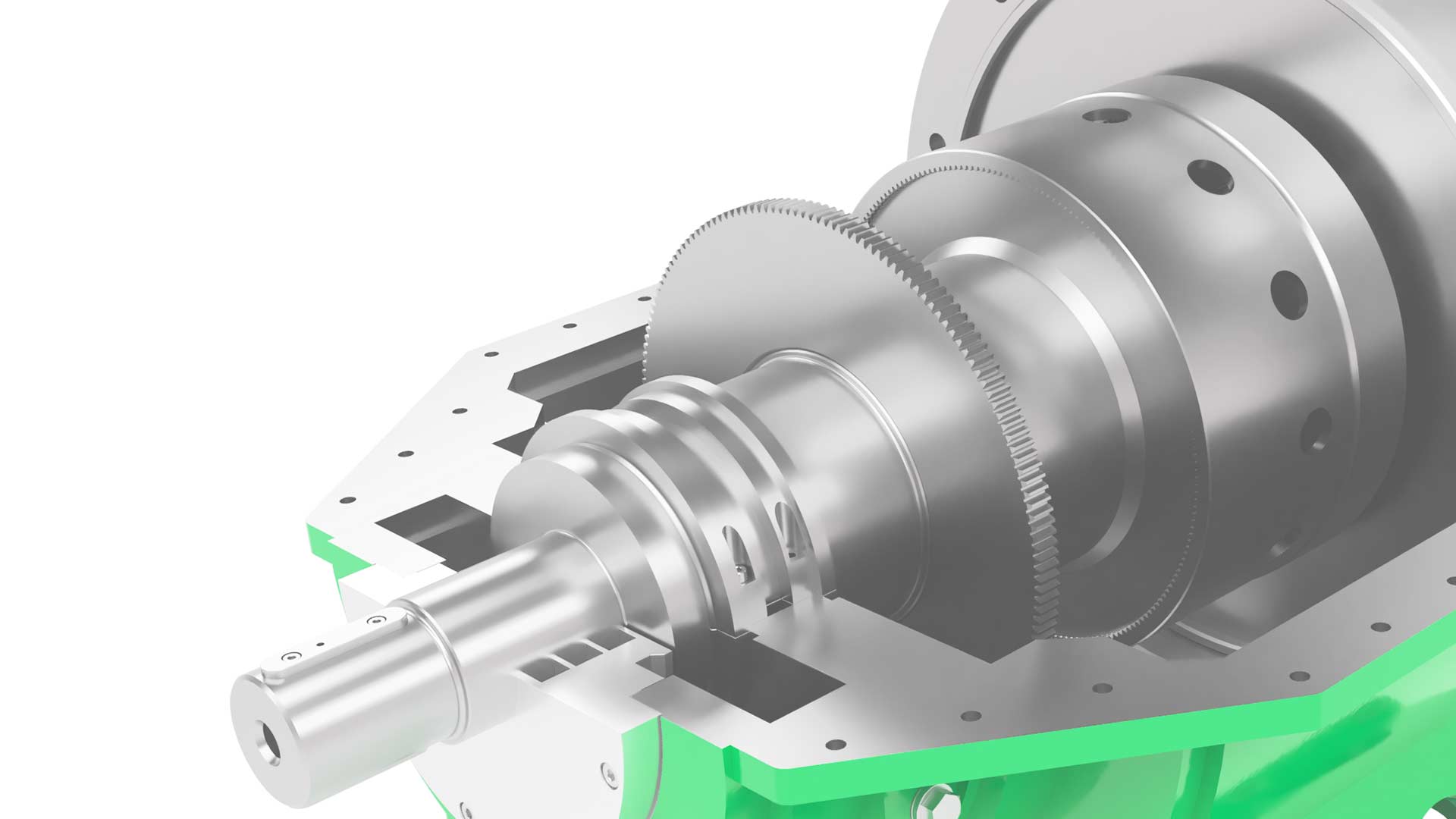

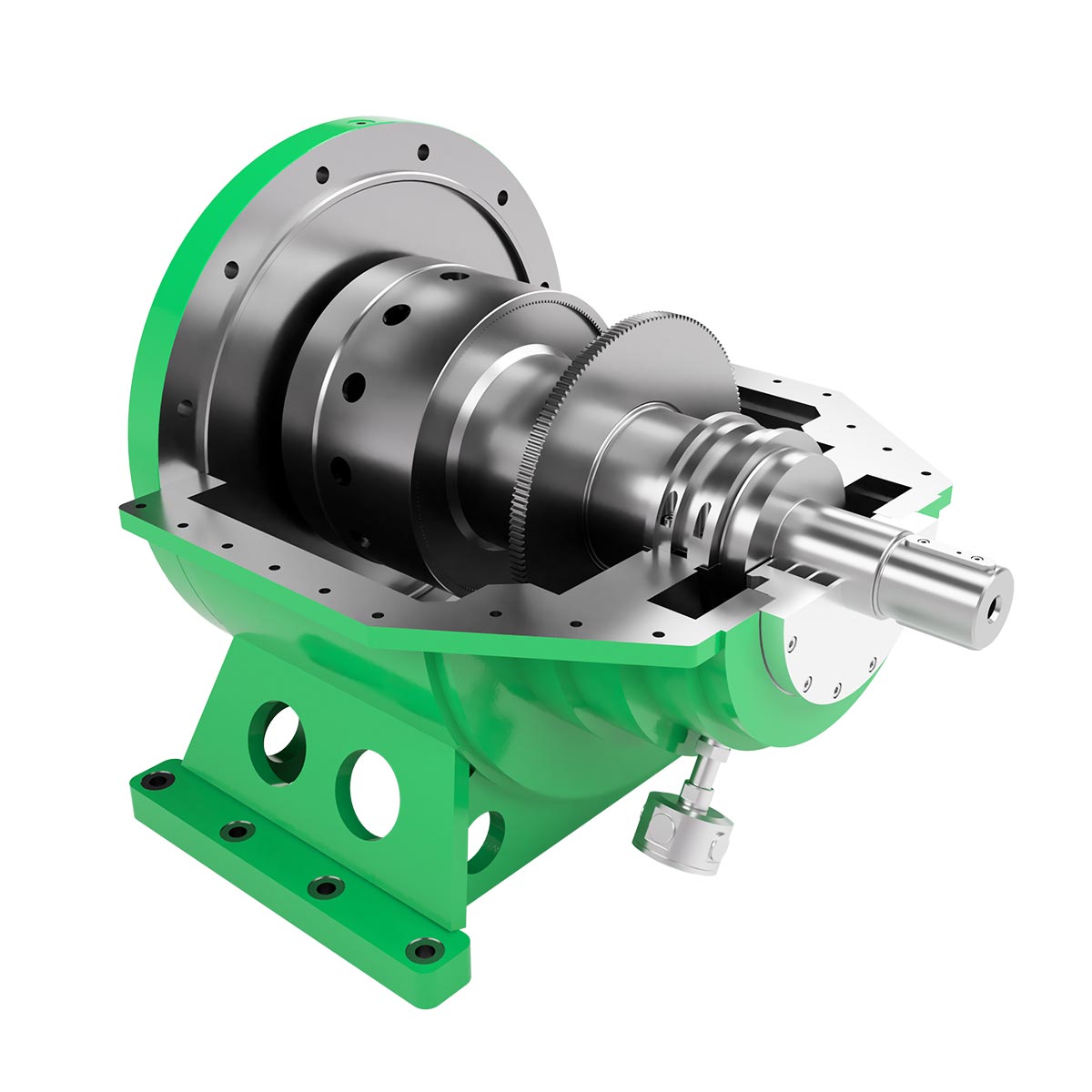

| Design | With fixed or rotating planet carrier, self centering sun wheel and thin, flexible annulus for optimized power distribution |

| Gears | Spur gear or double helical toothing |

| Casing | Fabricated casing, foot mounted, split line mounted, or flange design for direct connection with motor / generator |

My motivation:

“Manufacture turbogears at the highest level.”

Sebastian Besler, Production / Gearing

12 years of turbogear experience